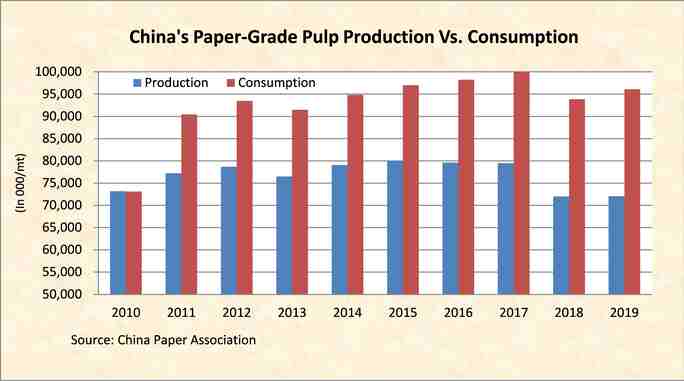

In its 2019 industry report, China Paper Association (CPA) confirmed that industry production of paper-grade pulp grew a little from the previous year to 72.07 million metric tons, yet still down -8.76% from its peak in 2015 as a result of massive closure of pulp mills who failed to meet with environmental protection requirements set by the government in recent years.

Apparently, difference between production and consumption became significant, surging from near-balance in 2010 to 24.02 million metric tons by 2019! And such huge gap had to be covered by imports of virgin wood pulp from overseas.

To secure fiber supplies, large Chinese paper and board producers have stepped up shipment of wood chips from overseas to pulp them in China, while actively buying wood pulp in the world market at the same time. This has led to the consistent increase in the country’s virgin wood pulp production, which hit 12.68 million metric tons in 2019, or +10.55% from that of 2018. On the non-wood sector, bamboo pulp production, an emerging fiber source, maintained its positive growth momentum by rising +9.42% to 2.09 million metric tons in 2019, contrary to further declines in traditional non-woods, such as straw and bagasse, in pulp production.

More industry observers in China are now hopeful of a growing role that bamboo pulp will play in the future of the industry, seeing the length of bamboo fiber in-between that of hardwood and softwood. Also, bamboo resources are ample, especially in southern and southwest China. In addition to successful stories in tissue paper production, exploration to diversify bamboo pulp application is now underway on other grades of paper and board. Under more uncertainties in recovered paper supply at home and abroad, tapping the potentials of bamboo becomes a cost effective option for the industry, experts say.